by Twinsavergroup | May 22, 2017 | Press Releases

Garth Towell, Twinsaver Group CEO, said, “We are very excited to welcome the Validus team to the Twinsaver family. The acquisition is a significant move forward for our business as it will enable us to further diversify our product proposition, service new consumer segments and accelerate Validus’ growth through investments into technology, talent and access to wider networks.”

Established in 2005, Validus has grown its national portfolio of quality disposable medical products across South Africa’s hospital, frail care and baby care industries. Known for brands like Clemens and Bumbies, the sale will provide Validus with the capital required to expand into ancillary and new categories.

Twinsaver acquires Validus Medical

Commenting on the decision to sell, Folkmar Geyer, managing director at Validus Medical said, “The synergies between Twinsaver and Validus are many; both businesses are market leaders, our products are complementary and our heritage, proudly South African.

The added advantage is that the sale will help increase Validus’ production efficiencies and as a wider business, will help bolster the output of South Africa’s manufacturing industry.” “South Africa’s manufacturing sector has been widely publicised as a gateway to enhancing the global competiveness of the country,” said Towell. “With the sector contributing more than 15% to the national GDP, we believe our business and the investments we make, play a vital role in unlocking the deeper potential within the sector. “What’s particularly encouraging are the findings in the Industrial Development Corporation’s 2016 Economic Overview which ranked the business confidence in the paper and paper products industry above all other manufacturing sub-sectors.” The sale is subject to regulatory and Competition Commission approval.

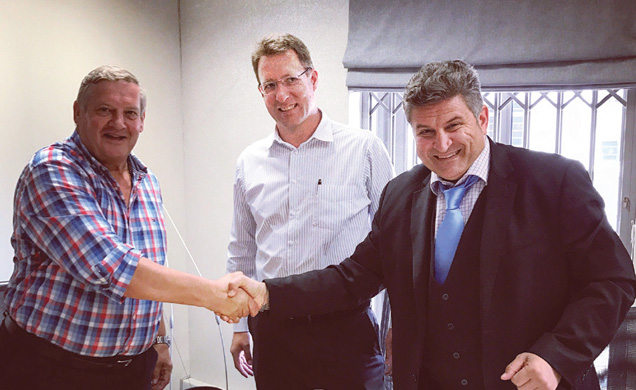

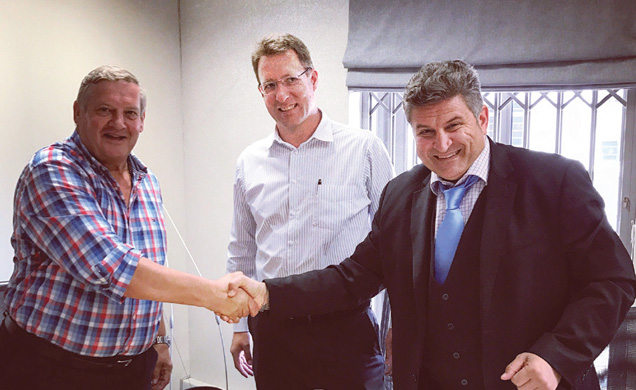

MORE ABOUT VALIDUS MEDICAL Validus Medical employs more than 75 people across South Africa. Its factory is located in the Ekandustria industrial area of Bronkhorstspruit. The company operates high speed, fully automated production lines for adult diapers, feminine hygiene products, baby diapers, wipes, draw sheets and linen savers. ABOVE LEFT, RIGHT Validus brands of disposable hygiene products include Clemens adult diapers and linen savers, and Bumbies wipes. ABOVE CENTRE, left to right: Folkmar Geyer, managing director at Validus Medical; Dion de Graaf, Chief Operating Officer at The Twinsaver Group and Garth Towell, CEO, The Twinsaver Group.<

by Twinsavergroup | Feb 14, 2017 | Press Releases

The company, which has been operating in South Africa for over 60 years, has announced an investment of R580 million (US$42 million) at its Bellville and Kliprivier operations in the Gauteng and Western Cape provinces respectively.

“The production will serve the domestic market and export to neighbouring countries comprising Angola, Botswana, Democratic Republic of Congo (DRC), Lesotho, Malawi, Mozambique, Namibia, Swaziland, Tanzania, Zambia and Zimbabwe, thus extending its footprint in sub-Saharan Africa and entrenching its position as the leading tissue producer, ” said Chief Executive Officer of Twinsaver, Garth Towell.

The R500 million investments by Twinsaver at its Kliprivier, Ekurhuleni manufacturing operation in Gauteng will involve the construction of new facilities and the installation of a new tissue-manufacturing machine.

The Kliprivier manufacturing plant is expected to take 15 months to complete and will increase the annual output of 59 000 tonnes by 27 000 tonnes.

The Ekurhuleni Executive Mayor, Mzwandile Masina, welcomed Twinsaver’s investment expansion in the Ekurhuleni Municipality.

He highlighted that manufacturing held an important role in the process of economic development in the country and region.

Twinsaver has five production locations in South Africa with its head office located in Bryanston, Johannesburg, employing 769 people.

Twinsaver already invested R 80 million at its Bellvile factory in August 2016, completing phase 1 with the installation of a two-ply converting line which will double production capacity and create additional employment across the tissue value chain.

Twinsaver’s investment at its Kliprivier manufacturing operation received support from the Department of Trade and Industry’s 12i Tax Allowance incentive scheme to the value of R 180 million.

Minister of Trade and Industry, Dr Rob Davies, lauded the R 580 million investment.

“This investment expansion made the investment is indeed commendable and resonates well with our industrial policy of building local production capacity and gearing up for export markets,” said Davies.

- Source: http://allafrica.com/stories/201610110542.html

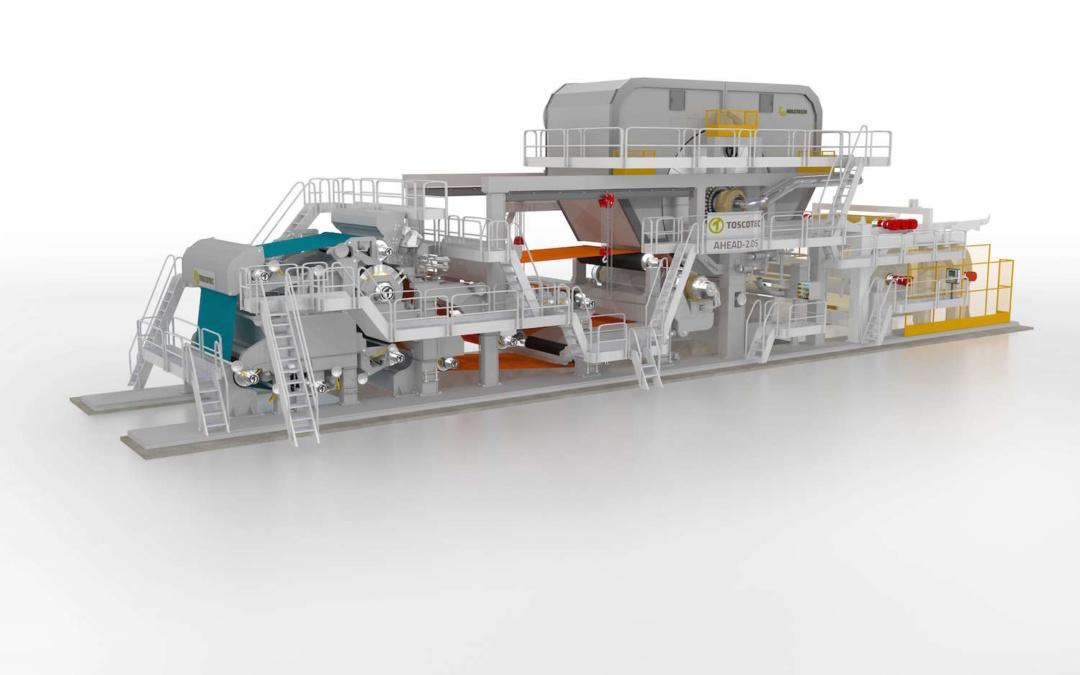

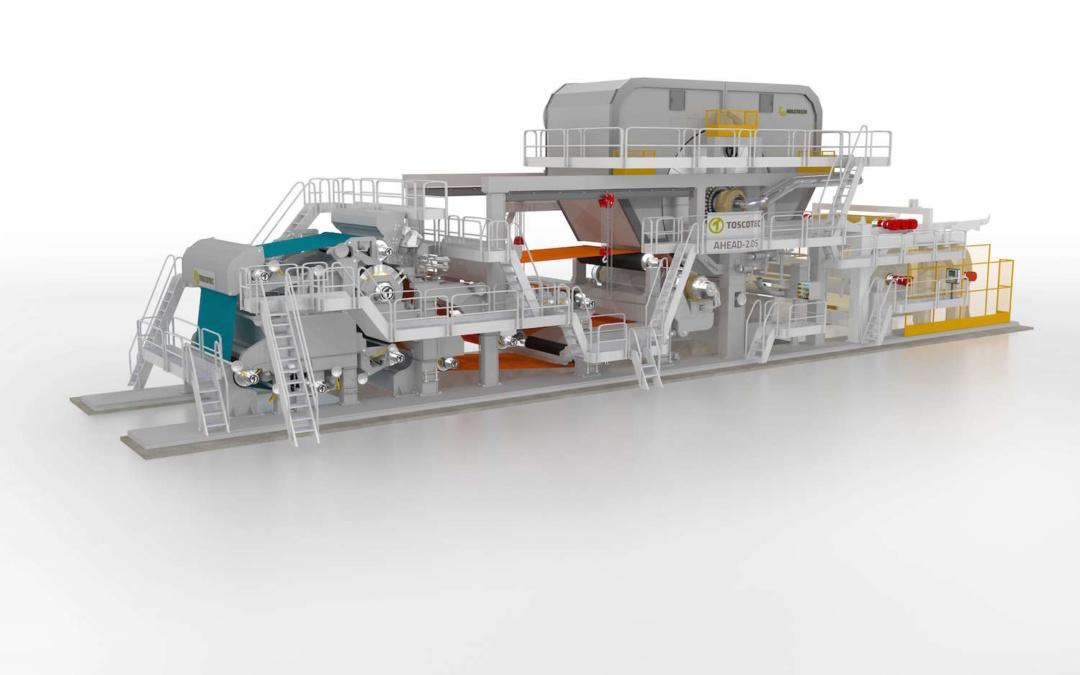

- Image source: http://www.toscotec.com

by Twinsavergroup | Dec 16, 2016 | Press Releases

Twinsaver Group, the major manufacturer of tissue products in South Africa, will proceed with a R500 million ($37 million) investment in the country’s local manufacturing sector by investing in a state-of-the-art new plant at its Kliprivier operations site in Gauteng, South Africa. The line, supplied by Toscotec, will be started-up in the last quarter of 2017.

The turn-key delivery for the new TM#5 will include a stock preparation system for virgin pulp, an AHEAD-2.0S tissue machine, tissue machine and plant auxiliaries, electrification & control systems. Full engineering, erection, erection supervision, training, start-up and commissioning complete Toscotec scope of supply.

The tissue machine will have a width of 2.75 m and will be designed for 2,000 mpm speed. The new line will produce, among the other grades, high-quality super-soft toilet tissue.

Twinsaver Group is the number 1 South African manufacturer, marketer and distributor of branded tissue products.

Toscotec is a turnkey projects supplier to the global paper industry.

Source:

- http://www.lesprom.com/

- http://bit.ly/2hB7QRA

by Twinsavergroup | Nov 17, 2016 | Press Releases

The CEO of Twinsaver, Mr Gary Towell said they have committed R580 million as part of the company’s strategic investment programme in South Africa. The R580 million has been committed to the country’s local manufacturing sector, investing in state-of-the-art production equipment at its Bellville and Kliprivier operations.

“Twinsaver has five production locations in South Africa with its head office located in Bryanston, employing 769 people. The R 500 million investments by Twinsaver at its Kliprivier manufacturing operation in Gauteng will involve the construction of new facilities and the installation of a new tissue manufacturing machine,” said Towell.

The Kliprivier manufacturing plant is expected to take 15 months to complete, and will increase the annual output of 59 000 tons by 27 000 tons.

“The production will serve the domestic market and export to neighbouring countries: Namibia, Botswana, Zimbabwe, Swaziland, Lesotho, Zambia, Mozambique, Tanzania, Malawi, Angola, and DRC – thus extending its footprint in sub-Saharan Africa and entrenching its position as the leading tissue producer,” added Towell.

Twinsaver already invested R 80 million at its Bellville factory in the Western Cape in August 2016, completing phase 1 with the installation of a 2-ply converting line which will double 2-ply production capacity and create additional employment across the tissue value chain.

The Ekurhuleni Executive Mayor, Councillor Mzwandile Masina also welcomed Twinsaver’s investment expansion in the Ekurhuleni Municipality. Speaking at the ceremony Mr Masina spoke on business support in the Ekurhuleni region, highlighting that manufacturing holds an important role in the process of economic development in the country and region.

Twinsaver’s R 500 million investment at its Kliprivier manufacturing operation in Gauteng received support from the Department of Trade and Industry 12i Tax Allowance incentive scheme to the value of R 180 million.

Issued by: Department of Trade and Industry

South African Government (Pretoria)

http://allafrica.com/stories/201610101185.html

by Twinsavergroup | Nov 9, 2015 | Press Releases

The programme also comprises a structured workplace training component which equips the participants with the necessary skills and competencies to enable them to further a career in tissue making. This programme not only opens promotional, growth and further job opportunities for participants, but also strengthens the company’s skills base.

Minimum requirements:

- Applicants must be currently unemployed.

- Applicants must have passed Grade 12 or NQF level 4: English (65% and above) and Physical Science (75% and above) and pure Maths (75% and above)

- Applicants must not have more than a Grade 12 or NQF level 4 qualification.

- Participants must not have participated in any Seta registered learnership.

- Only SA citizens are eligible to apply.

- Applicants must be motivated, keen to learn and willing to put in the effort to succeed

Applications will be accepted annually during October.